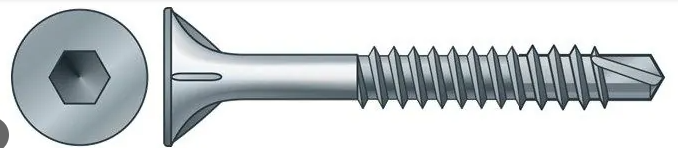

Bugle Batten Screws

Bugle Batten Screws, also known as Batten Screws, are a specialized type of fastener designed for securing wooden battens or furring strips to solid surfaces, such as masonry or concrete walls.

Key features of Bugle Batten Screws include:

Bugle Head Design:

The screw head has a rounded, countersunk profile that creates a flush, smooth finish when installed.

This "bugle" shape allows the head to sit flush with the surface of the batten or furring strip.

Threaded Shaft:

The shaft of a batten screw has a coarse, aggressive thread pattern.

This thread design is optimized for gripping into the wooden batten or furring strip.

Expansion Mechanism:

Batten screws often have an expansion mechanism, typically in the form of a split or slotted sleeve around the shaft.

When the screw is driven into the pre-drilled hole in the masonry or concrete, the expansion mechanism creates a tight, secure grip within the hole.

Hardened Steel:

Batten screws are usually made from hardened, corrosion-resistant steel, such as stainless steel or case-hardened steel.

This ensures the screw can withstand the high stresses of being driven into dense, solid materials without breaking or deforming.

The key benefits of Bugle Batten Screws include:

Secure Attachment: The combination of the coarse thread design and expansion mechanism provides a strong, vibration-resistant hold for the wooden batten or furring strip.

Flush Finish: The bugle head design allows the screw to be driven flush with the surface, creating a clean, uniform appearance.

Versatility: Batten screws can be used to attach a variety of wooden furring strips, battens, or other building materials to solid masonry or concrete surfaces.

Durability: The hardened steel construction and corrosion resistance ensure the screws maintain their integrity in harsh environments.

Bugle Batten Screws are commonly used in construction, renovation, and interior finishing applications where wooden battens or furring strips need to be securely fastened to masonry or concrete walls.